We just finished shipping Phobos 2.5 and it’s a massive performance upgrade over previous versions of Phobos.

For those that are not aware: Phobos is our commerical OpenTelemetry add-on for Akka.NET.

This past summer we posted about Phobos 2.4’s performance being 62% faster than Phobos 2.3.1 Phobos 2.5 is 161% faster than Phobos 2.3.1 - and in this post we’re going to share the generalized .NET performance optimization technique we’ve been using to accomplish these improvements: deferred allocations.

Problem Context

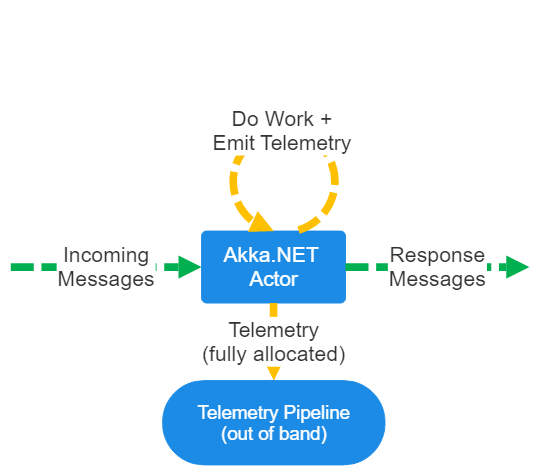

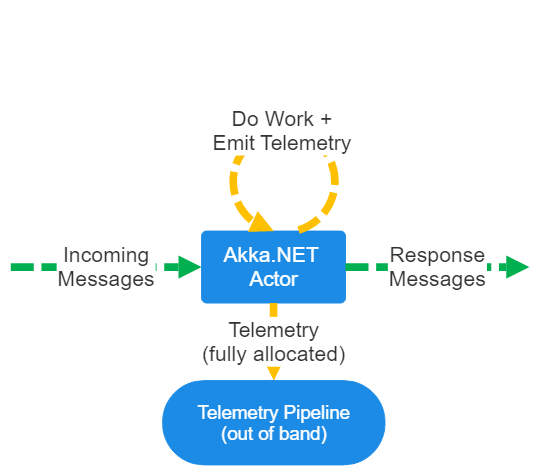

Imagine you have a performance-critical hotpath in your application, such as an Akka.NET actor or an ASP.NET Controller - we ideally want to keep the latency in this critical path as low as possible in order to maximize responsiveness and per-process throughput.

But, we are also given a secondary requirement - maybe we have to add logging or OpenTelemetry tracing here for observability purposes, or maybe we have to push some data points into an internal-facing analytics / reporting system for internal stakeholders.

Implementing that secondary requirement along the critical path is going to increase our processing time at the expense of our mission-critical processing and ultimately, our end-users. Deferring allocations to outside the critical path is how we can avoid this problem.